Vehicle Nosecone Project for EV 2025

Fall 2024, Columbia Formula Society of Automotive Engineering

Project Overview

Research, develop, design, test, and implement a new nosecone. Optimize for performance. Win SAE 2025 Comp!

Problems and Issues Needed To Be Solved:

Redesign the nosecone geometry for optimized aerodynamics

Change the material from dacron to a material better suited for high-performance

Prevent nosecone from dragging on the pavement

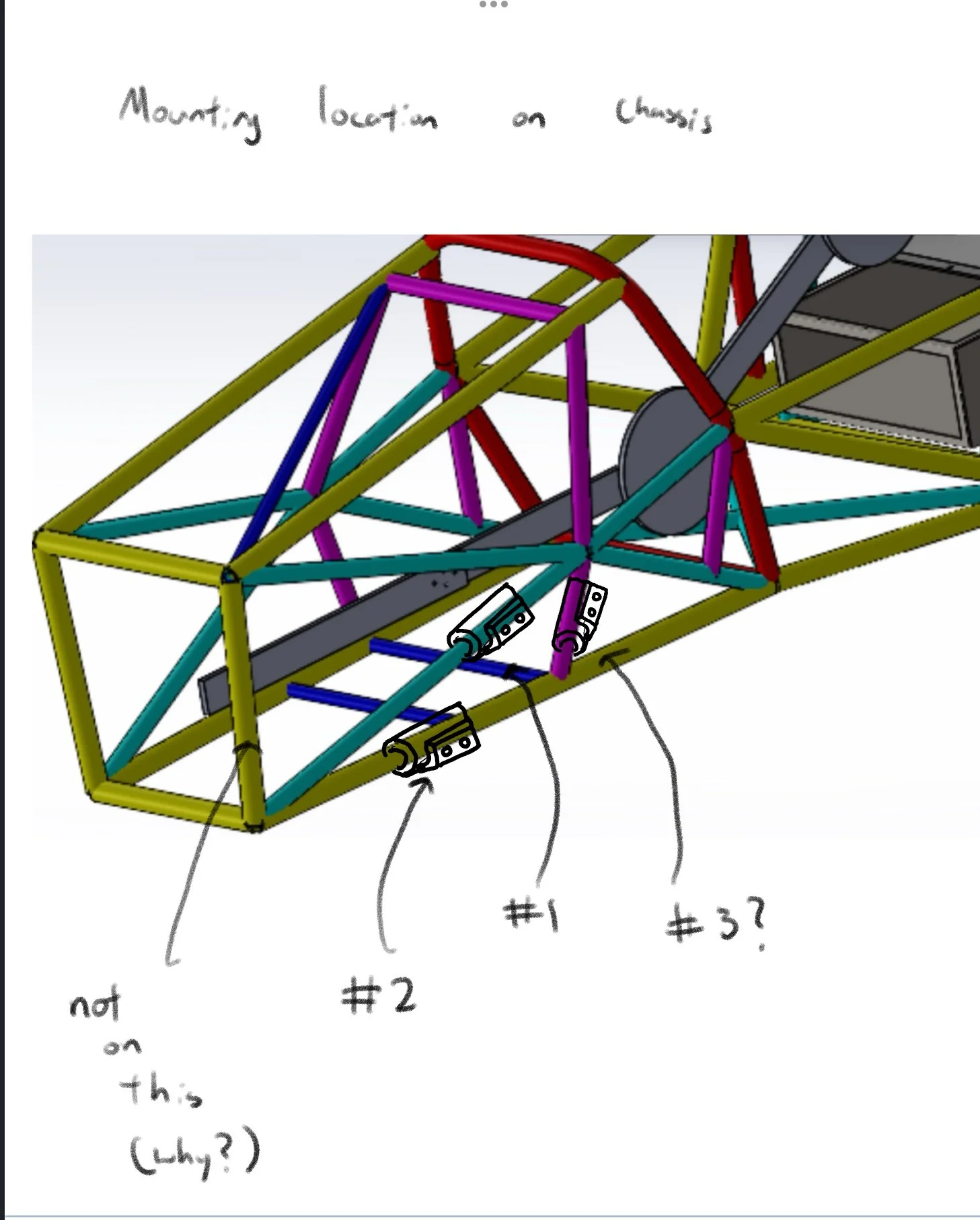

Create brackets/mounts so the new nosecone needs to align perfectly with the Chassis 2025 design

Design and Testing Process

CAD Modeling of Nosecone

Design Intent:

Smoothed contour to follow the shape of the 2025 Chassis, best for Aerodynamics and attaching to the body.

Design Process:

Identified the weak points of the current nosecone manually.

Used Solidworks to remodel the geometry (3D sketch guidelines, lofted extrude, planar mates, create a part in assembly)

Worked closely with the Aerodynamics team for design iterations.

EV 2026 Design In Progress!!!

Challenges:

2. Materials Research & Mold Building

Research Intent: Change the material of the nosecone from Polyester Fiber (Dacron) to Carbon Fiber. Conduct background research on the material properties and molding techniques for different materials.

Research Outcomes: Researched, developed, and received approval for a molding technique for CF.

Challenges: Creating the CF lay-up and molding method given our resources and constraints. Budget, machinery (w/out CNC foam cutter) etc.

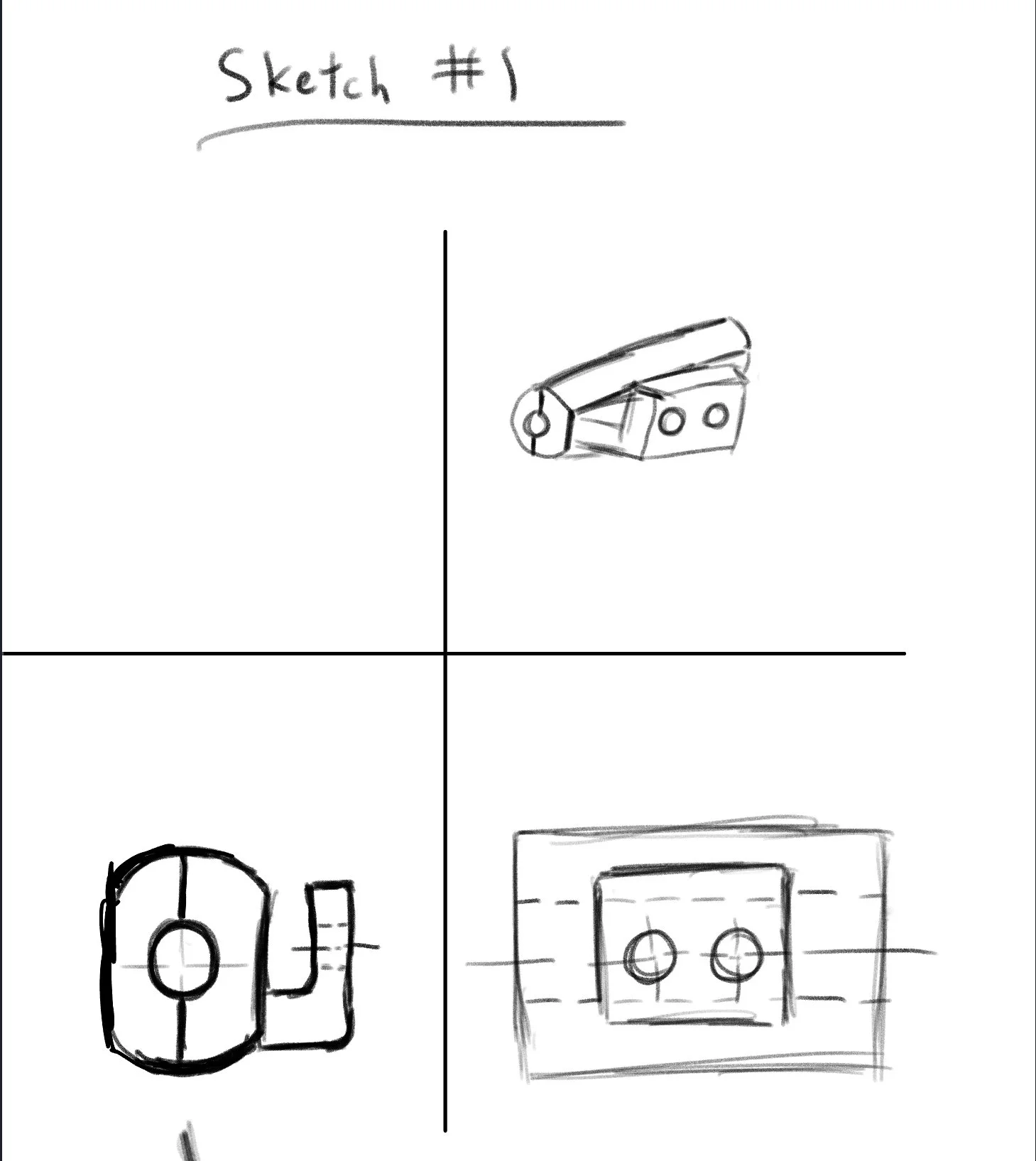

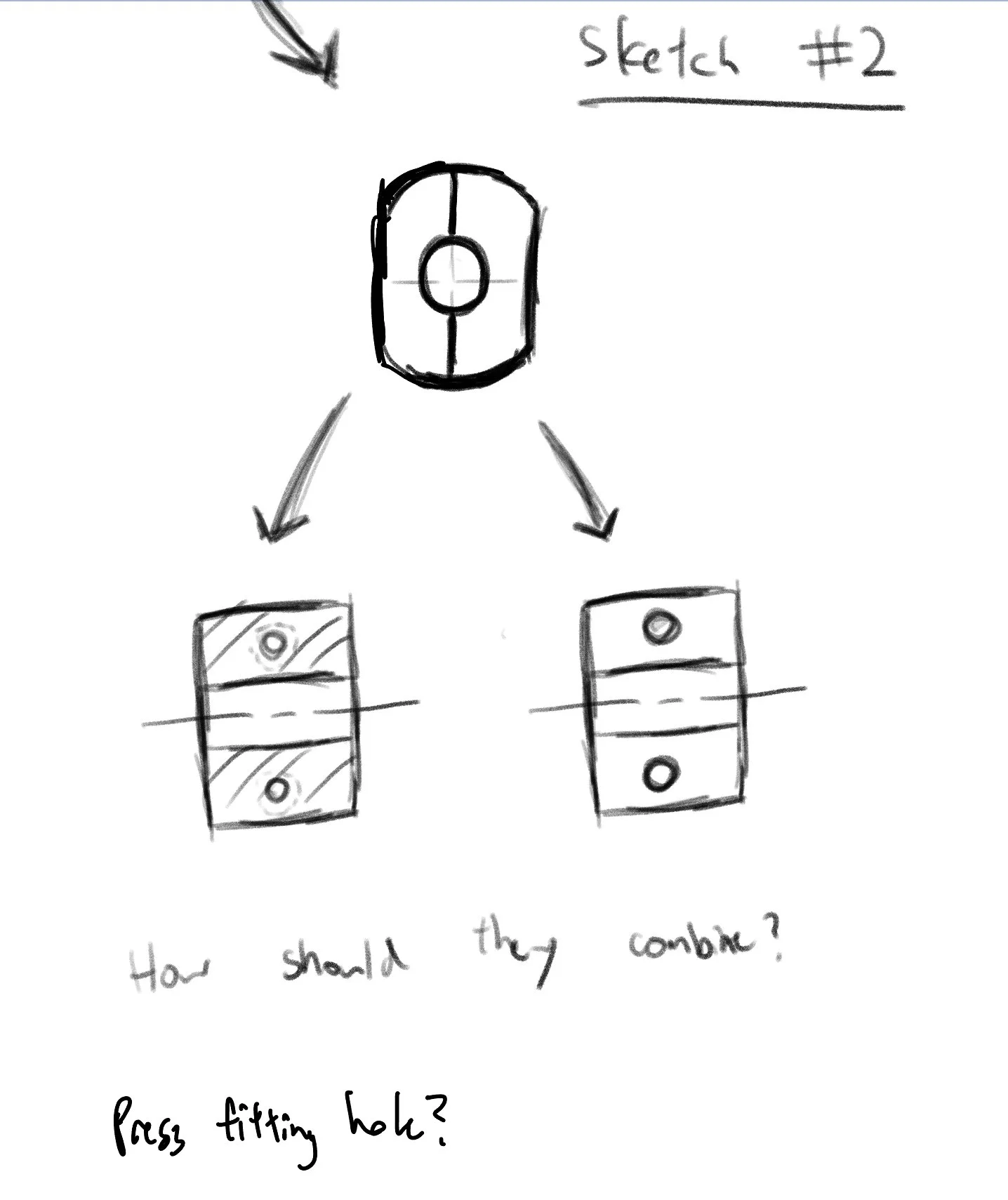

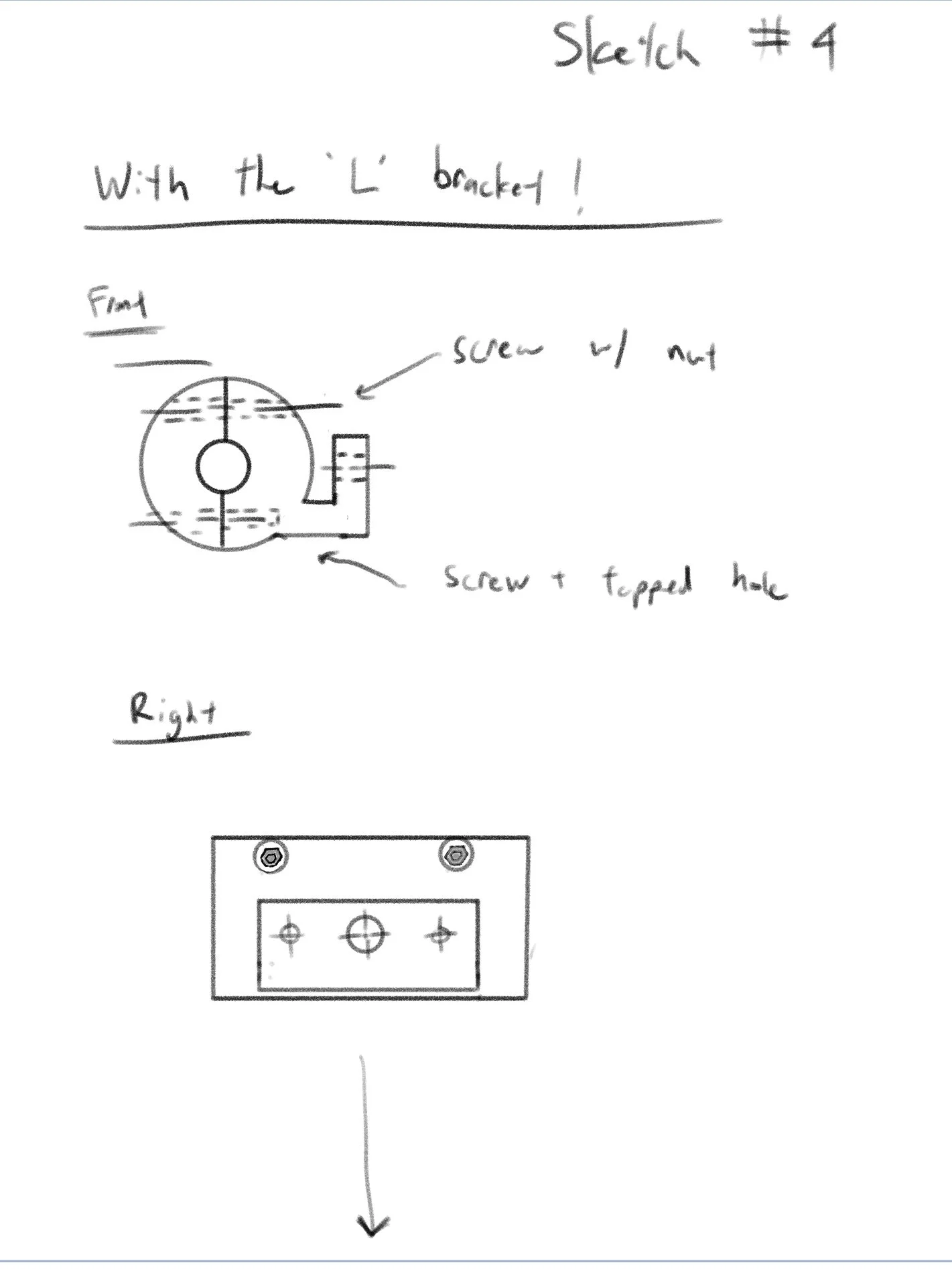

3. Brackets and Mounts 3D Design & Manufacturing

Design Intent: Create four brackets that function to mount the nosecone on the chassis. Create a shaft-coupling-like bracket with an L-shaped structure.

Challenges: Designing a clamp-structured bracket that can be screwed together and has an L-shaped component on a cylindrical solid. Previous year chassis had welded components used to mount the nosecone. Need to consider the position of the brackets and functionality (easy of putting NC on)

4. Aerodynamic Testing!

CFD and Hand-written analysis of external flow fluid dynamics of a nosecone. Calculate/Manipulate Drag and Lift

Project Outcomes

Updated & Optimized Nosecone Geometry + Materials

Theoretical Calculation yield, 21.8% decrease in drag force

11.5% decrease in weight

6 x Brackets + Mounts Created, Successfully creating a binding mechanism

Created a Foam Male Mould for Carbon Fiber Layup, can be reiteratively used

Convenience Factor: no longer need to take suspension off to attach and detach nosecone.